Vessels are a major component in installations for various procedures in almost all fields of industry. Many production processes require different substances that are stored in vessels and used in the individual processes later in the procedure. The vessels primarily store liquid, solid or gaseous substances, which are added to the process as and when required. Raw materials, fuels or end products are usually stored in large storage tanks.

Insulation is important for procedural processes

It is often important to store the substances within certain temperature limits. If the temperature is too high or too low, the substance can spoil or set, or lose its flowing properties and become incapable of being pumped or discharged. Insulation is therefore a major factor in the functionality of procedural processes.

Advantages

- Reduces heat losses

- Guarantees protection against contact by minimising the surface temperature

- Reduces cooling of the stored substance, so it remains fluid and does not set

- Prevents the vessel from freezing (with additional tracers)

- Prevents heating of the stored substance (for example, through solar radiation)

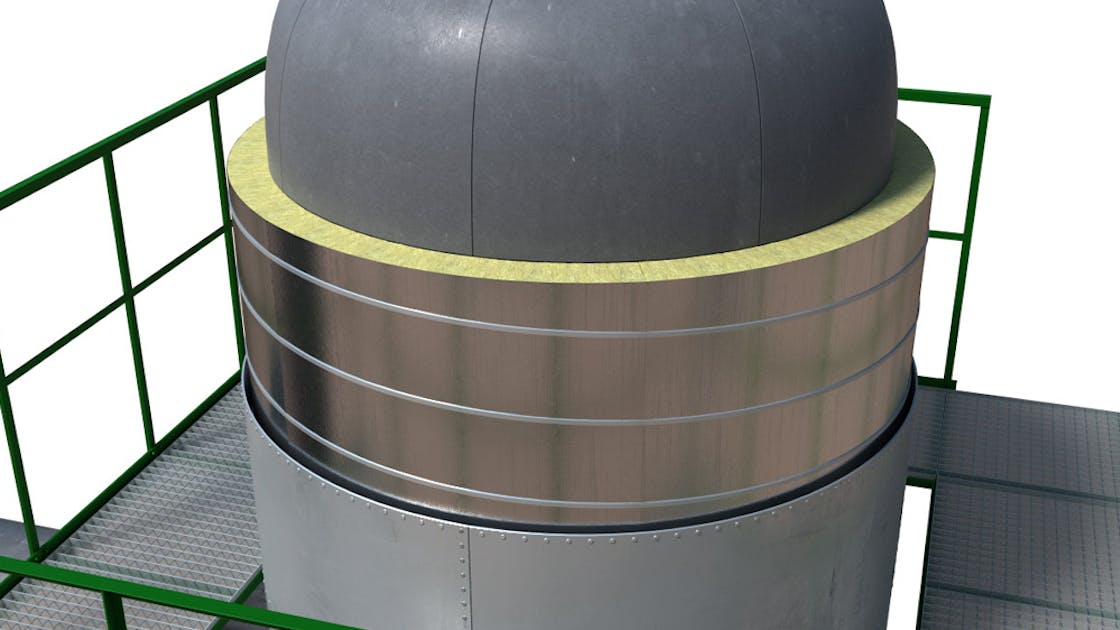

Insulation systems for vessels

An insulation system for a vessel generally consists of the following components:

- Insulation

- Support construction and a spacer

- Water vapour retarder with cold insulation systems

- Cladding

The actual operating temperature (above or below ambient) is essential for the design of the insulation work.

Find your local product assortment

You are now on our global website. ROCKWOOL Technical Insulation provides customers in some countries local product assortments and several assets like catalogues and product datasheets in their local language. Choose your country to find all the local information and contact details of our technical sales consultants.